Industrial Process Engineering. Design and Construction of Plants and Lines for Manufacturing

Efficient Design of Production Plants

ETD Inox Industries, collaborates as a partner of AMPHORA PROCESS ENGINEERING (amphoraprocess.com) for the development of complete plants at the process engineering level.

Thanks to its experience and a great team of professional engineers, we are specialists in carrying out process engineering developments, whose purpose is to efficiently design a production plant.

We analyze all the technical data to carry out the implementation of all the necessary elements for the optimal functionality of a factory in terms of storage, conduction, dosing, agitation, and packaging of liquid and solid products.

We study the times required for the elaboration of the proposed product and, we develop the complete diagrams to carry out the pertinent manufacturing and installation.

In this way, ETD Inox Industries, together with AMPHORA PROCESS ENGINEERING, offers our clients the process engineering service and, the manufacturing of all its elements, also completing all the strata in terms of efficient solution, development, implementation, manufacturing, installation of equipment, accessories, and instruments that a production plant in the food, chemical, and cosmetic sectors needs.

Comprehensive Solutions for the Construction of Production Plants

In this way, ETD Inox Industries offers our clients the process engineering service and the manufacture of all its elements, also completing all the strata in terms of efficient solutions, development, implementation, manufacturing, installation of equipment, accessories and instruments that a production plant in the food, chemical and cosmetic sectors need.

Our Goal for your Processing Line

The objective is to guarantee the performance of our clients, from an economic, sustainable and safe perspective.

Listen

We listen to the needs of our clients.

Analysis

We analyse the physical and chemical characteristics of the products to be processed or dosed.

Measurement

We measure the production times that our clients require.

Optimization

We create and propose new options to improve production systems in terms of time and costs.

Control

We establish control systems.

Parameterization

We perform the parameterization of the entire system.

Flow Design

We develop flow diagrams and/or process P&ID.

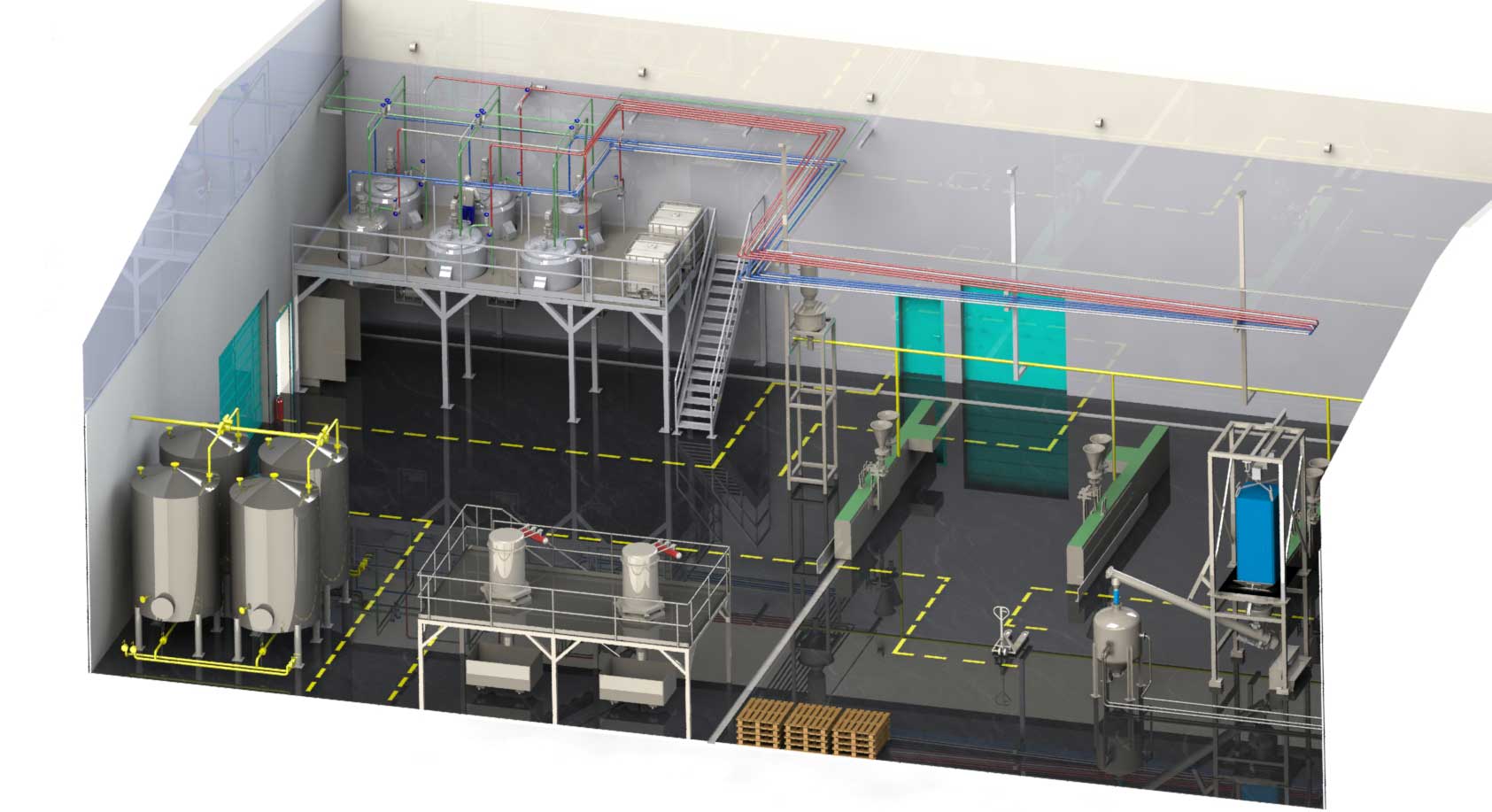

3D Development

We design our projects using 3D plans and rendering to offer a completely realistic view of your facilities.

Running Calculations

We carry out the calculations regarding the resistance of materials, structures and thermal exchanges.

Save Resources, Optimize Times and Boost your Production and Profitability

Your business objectives will be ours

Increase performance

We design our equipment and facilities to achieve the maximum production required

Cost reduction

We carry out the calculations and analyses to optimize the energy consumption of your installation as well as the auxiliary means in the execution of your projects.

Specialized Technical Support

Our work team interacts directly with you in the field to carry out the optimal development for your company.

Comfort for Our Clients

We are the only interlocutor to coordinate all the work in design execution and solve your problems.

Quality and Finishes

Thanks to our technical means, collaborators and specialized work team, we achieve the aesthetic finishes and qualities that your plant needs.

Pilot Plant for Pneumatic Transport

Our pilot plant makes us aware of your product to ensure the optimal result for pneumatic transport.

Services Offered in Our Process Engineering

Advice and Analysis

It is essential to collect all the data and premises of our clients in order to offer a personalized solution. Already in the offer phase, ETD Inox Industries carries out the initial advice and analysis to start the project with the objective data and obtain the solution from this moment. At ETD Inox Industries, we are aware of the importance of applying current regulations for perfect compliance with the installation in all its phases, which is why we are specialists in this field of action.

Design

Both for companies that need modifications to the existing plant and for companies that need a new installation, we carry out the design of all the production equipment that makes up the plant to achieve the specific products that each project needs.

Projects management

Each client needs a customized solution. From newly created plants to plant modifications in process, ETD Inox Industries coordinates all the stages that a project needs. From the design, continuing through the manufacture, installation of all the equipment and components, and the coordination of all the phases and auxiliary means that will be part of the operation, always in accordance with the property.

We show you some of our Projects in Plants and Process Lines

Need help or more information?

Contact Information for Spain

Información de Contacto para México, USA, América Central y Caribe

Contact Form

(*) Required fields

Your personal information is safeguarded as we comply with the RGPD (General Data Protection Regulation) and this is the information that you should know in this regard:

Responsible for the treatment: ETD INOX INDUSTRIES, S.L. Address of the person in charge: Pol. Industrial, Parcelas 52 y 53 – 02200 – Casas Ibáñez – ALBACETE Purpose: Respond to your requests and provide you with our services. Legitimation: We will only treat your data with your prior consent, which you can provide us with through the corresponding box established for that purpose. Recipients: In general, only the personnel of our entity that is duly authorized will be able to have knowledge of the information that we request. Rights: Know what information we have about you, correct it and delete it, as explained in the additional information available on our website.

FAQ’S

Which the starting data for a good development of Process Engineering are?

Usually, our clients transfer information in an increasingly concrete way through some initial needs. At this point, an exhaustive analysis of the boundary conditions and starting assumptions, as well as the internal and external variables that are going to take part in the engineering project, is mandatory. It is essential, therefore, in an initial study, and with the aim of being able to gather them and include them in a project report, a good collection of data referring to the following aspects:

- LAY-OUT: it is essential to know the possible layout of the field elements in order to be able to carry out an appropriate dimensioning.

- RAW MATERIALS AND PRODUCTS: it is essential to know, both in solid and liquid materials, physical-chemical properties such as density (specific weight), viscosity (in liquids), granulometry (in solids), corrosivity (pH), thermal conductivity, hygroscopicity and freezing and flash points. For this it is most useful to have the technical data sheets for each product.

- REQUIRED PRODUCTION: with the aim of setting the desired values of the installation to be implemented, and thus calculating the inputs and outputs in our system.

- APPLICABLE REGULATIONS: in accordance with current legislation depending on the products to be handled, as well as the requirements set for the application sector.

- DESCRIPTION OF THE PROCESS: when shaping the base project through an initial report and a process diagram, it is essential to know the type of unit operations to be carried out in each piece of equipment, from storage to final dosing. In this last section, it is vital to have the opinion and experience of the client when carrying out its preparations, for which at ETD we have the professionalism and closeness to the client, with the common goal of providing the best solution.

Which the applicable standards in the manufacture of Storage Tanks are?

Every day, and especially in chemical and petrochemical sectors, the need arises to store products that are harmful to health and the environment, either because of their toxic, corrosive, flammable nature or because they are under pressure. In this sense, current legislation establishes a series of requirements to be taken into account in the production process, with the aim of ensuring the quality, functionality and safety of the equipment in question. The manufacture must be carried out following the guidelines established by a prestigious Design Code, and the traceability of the materials, the supporting calculation, the welding homologation, tests and pertinent tests must be taken into account, as well as the periodic inspections by part of the notified body. These are the standards, regulations and Design Code under which we can manufacture:

- ITC MIE-APQ: Regulations for the storage of chemical products and complementary technical instructions.

- UNE EN 14015: Specification for the design and manufacture of steel tanks.

- API-650: Welded Steel Tanks for Oil Storage.

- UNE EN 13445: Pressure vessels not subjected to flame.

- AD MERCKBLATTER: Technical standards for pressure vessels.

- ASME: Boiler and Pressure Vessel Code.

At ETD you can find the necessary advice, as well as the preparation of all the documentation required by the Authorized Control Bodies.

What data are necessary for the calculation of a Heat Exchange?

Every day and especially in the chemical and petrochemical sectors, the need arises to store products that are harmful to health and the environment, either because of their toxic, corrosive, flammable nature or because they are under pressure. In this sense, current legislation establishes a series of requirements to be taken into account in the production process, with the aim of ensuring the quality, functionality and safety of the equipment in question. The manufacture must be carried out following the guidelines established by a Design Code of recognized prestige, and the traceability of the materials, the supporting calculation, the welding homologation, tests and pertinent testing must be taken into account, as well as the periodic inspections by part of the notified body. These are the standards, regulations and Design Code under which we can manufacture:

- ITC MIE-APQ: Regulations for the storage of chemical products and complementary technical instructions.

- UNE EN 14015: Specification for the design and manufacture of steel tanks.

- API-650: Welded Steel Tanks for Oil Storage.

- UNE EN 13445: Pressure vessels not subjected to flame.

- AD MERCKBLATTER: Technical rules for pressure vessels.

- ASME: Boiler and Pressure Vessels Code.

At ETD you can find the necessary advice, as well as the preparation of all the documentation required by the Authorized Control Bodies.

How can I reduce my current production times?

It can be improved from many points of view, one of them would be the optimization in the agitation times, for this a study of the existing agitation would be made and the possible improvement of a new system would be analyzed. Another option could be the use of preparation processes prior to our process in reactors, such as premix tanks or in-line mixers.

How can I add liquids and solids to my products and ensure correct repeatability and traceability?

With automated liquid or solid dosing systems. It is necessary to study the different raw materials of the client, their formats, quantities to be dosed, precision, etc. In this way, we can design an automatic system that guarantees the precision and times required.